A little extra care in the ordering of zippers can save a lot of trouble for everybody concerned. Because we custom make each order, it is impossible to alter the requirements once it is in production. Given below is a checklist of technical and commercial requirements that should be kept in mind before ordering zippers. Go ahead – print it!

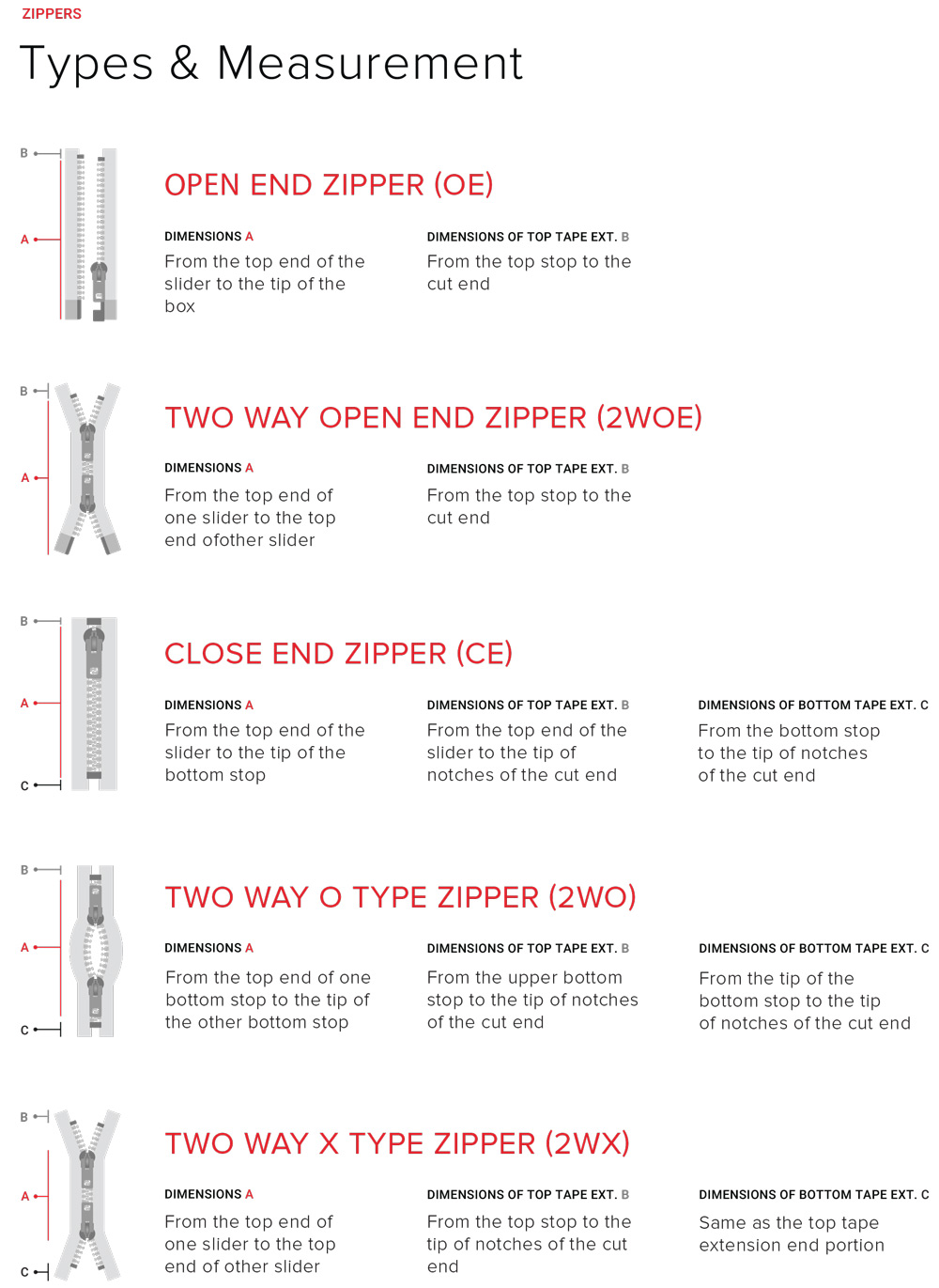

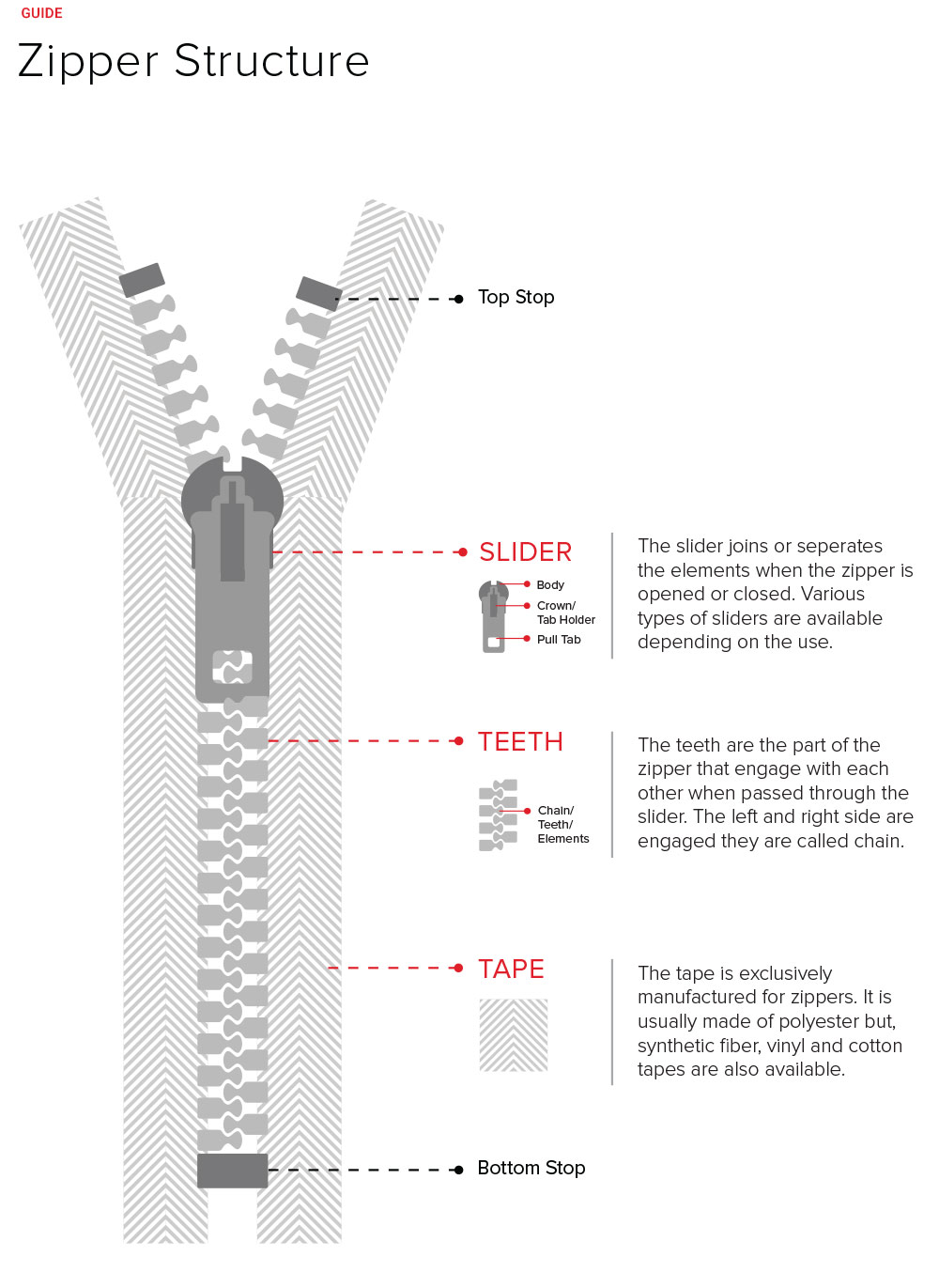

Type of Zipper

Specify whether the zipper is metallic, plastic, LFC or CFC, #3 or #5, closed end or open end, woven or knitted (in case of invisible zippers).

Type of Slider

Specify whether autolock, pinlock or no-lock sliders are required. If you need custom pullers, be sure to tell us that!

Color

Specify whether the color is from the standard shade card or from some other reference. Is color approval required before production?

Length

Assess the correct requirement from the garment. Make sure the length corresponds to the type of zipper measurement. For instance, in the case of a close-ended zipper, length should be measured from top of the top stop to the bottom of the bottom stop. For an open-ended zipper, length should be measured from top of the top stop to the bottom of the box & pin.

Quantity

Specify quantity required by type, color and size.

Finish

This specification is particularly important for metal zippers, where several finishes to the zipper slider are possible.

Delivery Date

Make sure both supplier and buyer are clear about the delivery date.

Special Requirements

AZO free, nickle free, heavy metal free and other such requirements must be specified in advance.