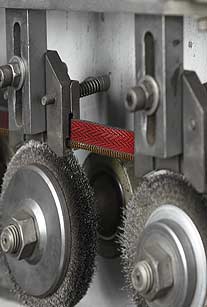

Tex Fasteners manufacturing is based on a hub-and-spoke model. Bulk components like textiles are centralized, while customized components are localised in each market. Tex has three fully owned zipper factories in Ho Chi Minh City (Vietnam), Dhaka (Bangladesh), Gurgaon (India) along with a Metal Trims factory in Bangladesh.

Large capacities and lean manufacturing techniques enable Tex to offer unlimited products at unmatchable lead times.